Manufacture of high temperature insulating textiles

Apronor >

Apronor offers a range of industrial, insulating and heat-resistant woven textiles with various treatments, in particular vermiculite and graphite impregnations, silicone, polyurethane or even PVC coatings and with aluminum lamination.

Insulation helps limit heat transfer and therefore reduce the amount of energy required to raise temperatures and protect adjacent materials from heat damage. Since the dangers of using asbestos were identified, several alternatives have been developed in situations where high temperatures are present. However, all technical textiles have one thing in common: providing textile solutions to the needs expressed by their users. Either they make it possible to produce finished products that could not be designed with other materials, or they provide a better solution than other materials from a technical or economic point of view.

Technical fabrics

Technical textiles are characterized by their specific technical skills and are intended for well-defined applications (insulation, waterproofing, impermeability, cut protection, electrical conductivity, etc.).

They provide a solution where flexibility of movement is needed, in situations where temperatures are extreme. Heat resistant materials capable of being made into fibers can be woven, braided, knitted or needled as needed.

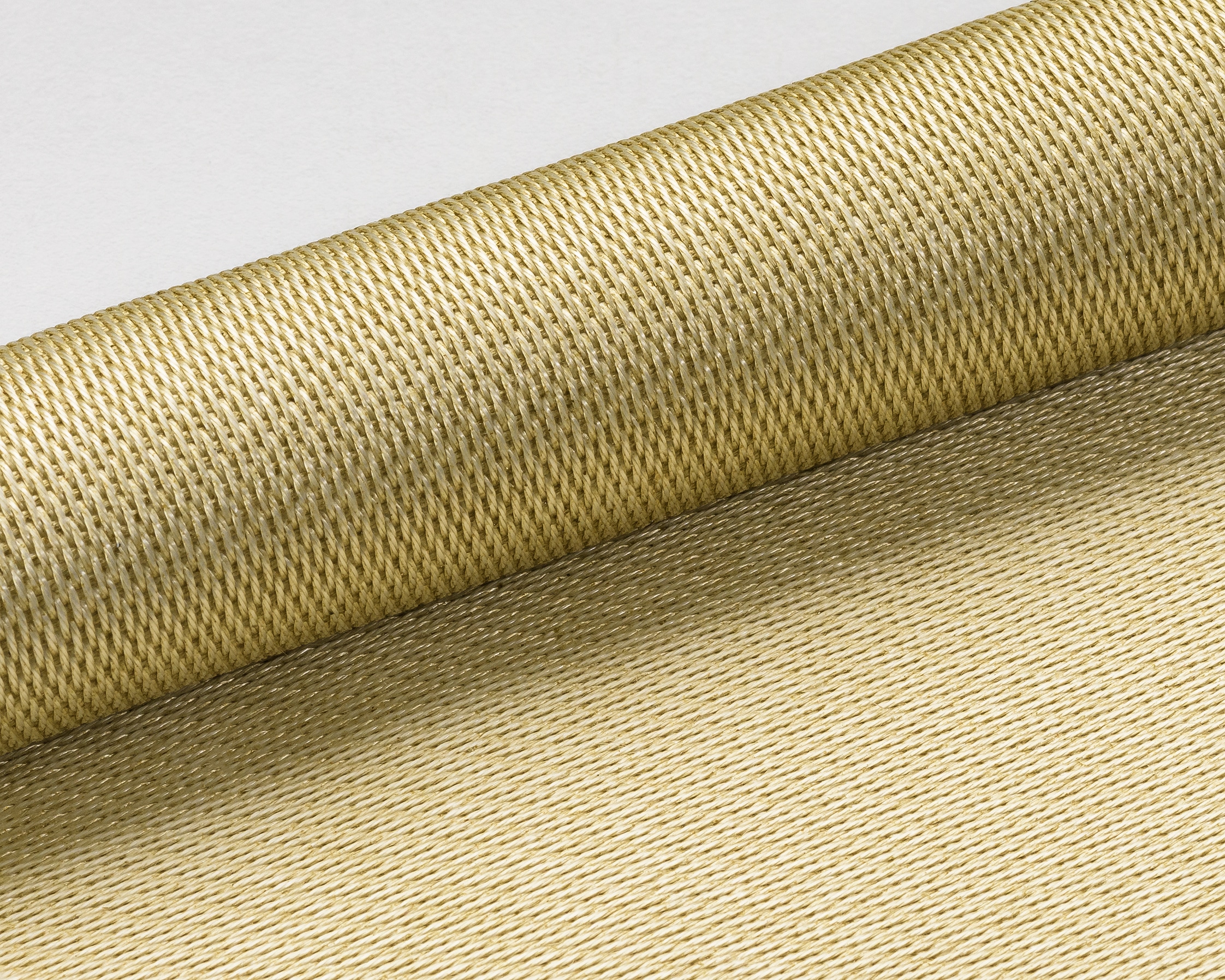

Aramid fabrics

Aramid fabrics, which are also known under the trade name Kevlar® or Nomex®, are heat resistant up to +/- 250 ° C. They allow thermal and sound insulation of materials used in several fields and their use is very widespread in ballistic applications.

Aramid fabric is made of fibers that retain excellent mechanical properties at high temperatures. They can replace glass fibers and metal and find their applications in tires, ropes, bulletproof vests and special materials intended for industry.

- Low thermal expansion

- High tensile strength

- Good chemical and abrasion resistance

- Great solidity

- Aeronautics/Aerospace

- Shipbuilding/Military/Ballistics

- Automotive (Belts, etc.)

- Sport/Ski slope/Water sports

These aramid fabrics have a polyurethane coating applied to their surface in order to modify their technical characteristics and appearance. The coating gives them the following characteristics: stain resistance, impermeability, abrasion resistance, antistatic, etc.

The aluminized aramid fabrics are intended for the manufacture of protective clothing and thermal insulation for example.

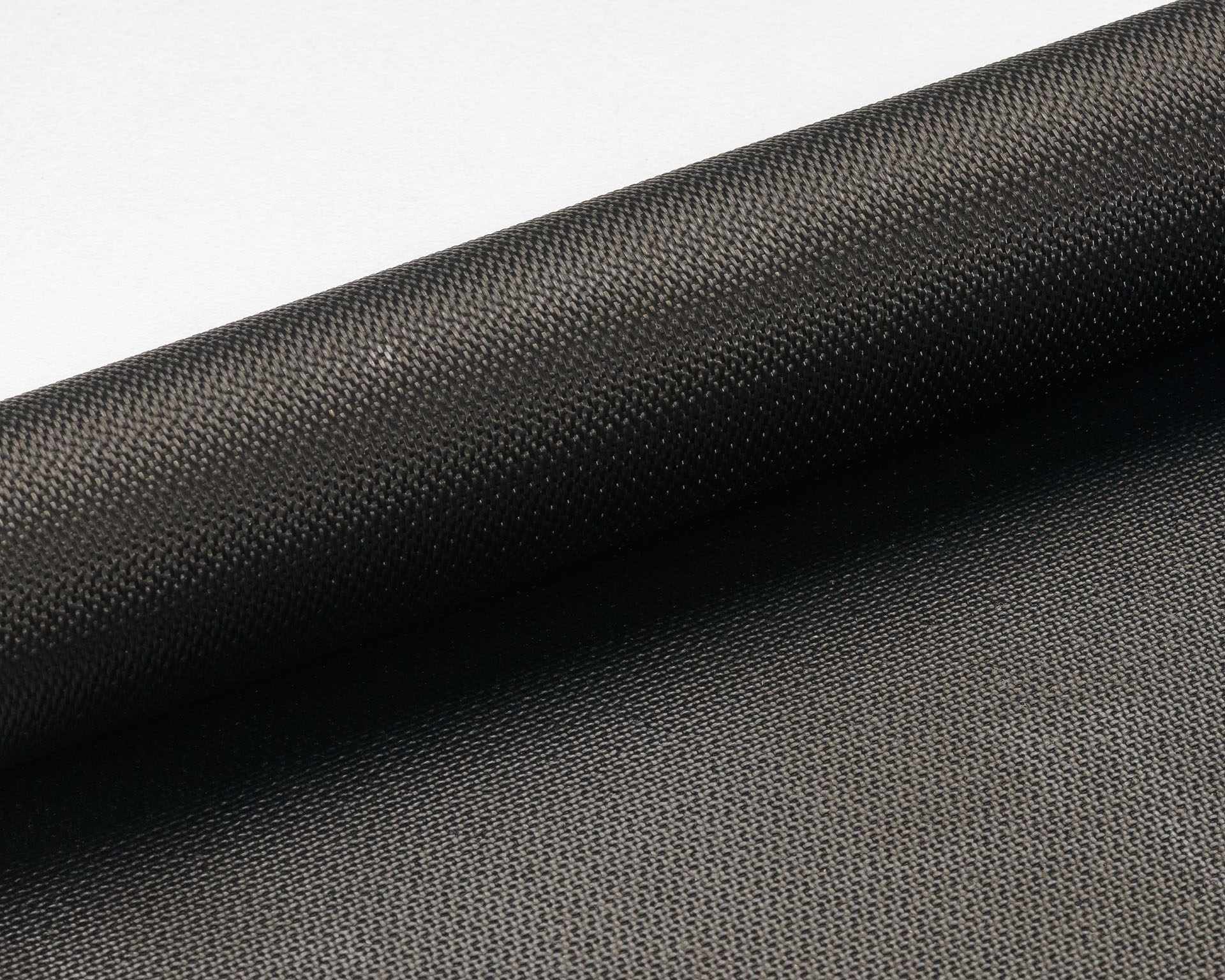

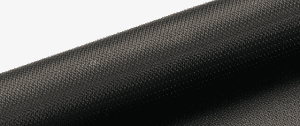

Carbon fabrics

Carbon fiber is a fabric made from a polymer that undergoes high temperature treatment, oxidation and carbonization. Composed of composite fibers and carbon atoms, carbon fabric is used to reinforce composite materials for applications requiring high mechanical strength at low weight. These fabrics use fibers produced under strictly controlled conditions and are subjected to numerous tests in accordance with a strict quality charter.

- Very high tensile and compressive strength

- Flexibility, adaptability & rigidity

- Electrical and thermal conductivity

- Chemical resistance and good abrasion resistance

- Good resistance to humidity

- Aeronautic and space industry

- Competition vehicle

- Sports equipment (boats, oars, sports bows, arrows, rackets, etc.)

| Reference | Composition | Weight (g / m²) | Width (mm) | Length (ml) | Armor | Wire | Sales packaging |

| 98130 | Carbon fiber | 163 | 1000/1250 | 100 | Cloth | 3K | Roller |

| 98131 | Carbon fiber | 163 | 1000/1250 | 100 | Twill 2/2 | 3K | Roller |

| 98140 | Carbon fiber | 204 | 1000/1250 | 100 | Cloth | 3K | Roller |

| 98141 | Carbon fiber | 204 | 1000/1250 | 100 | Twill 2/2 | 3K | Roller |

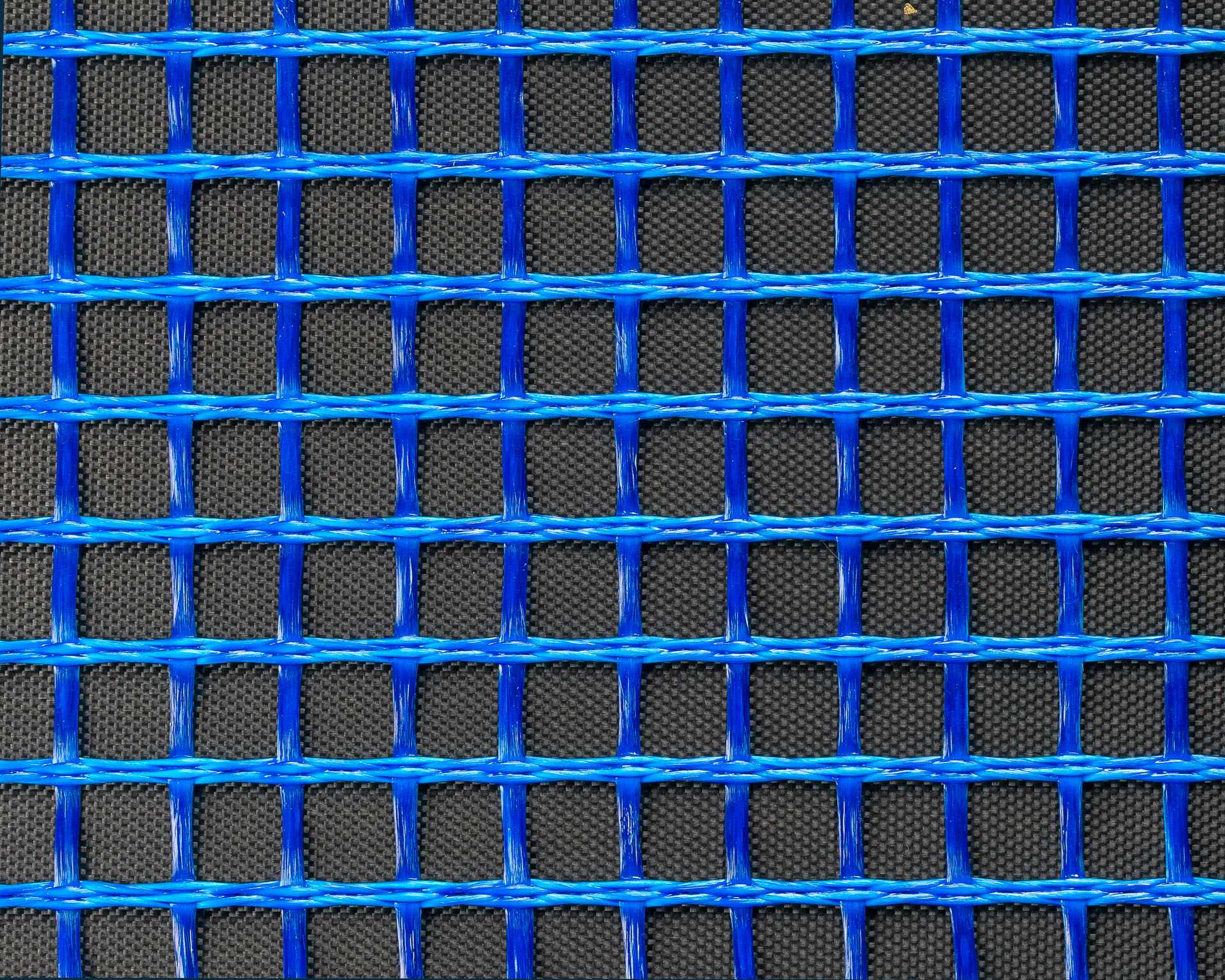

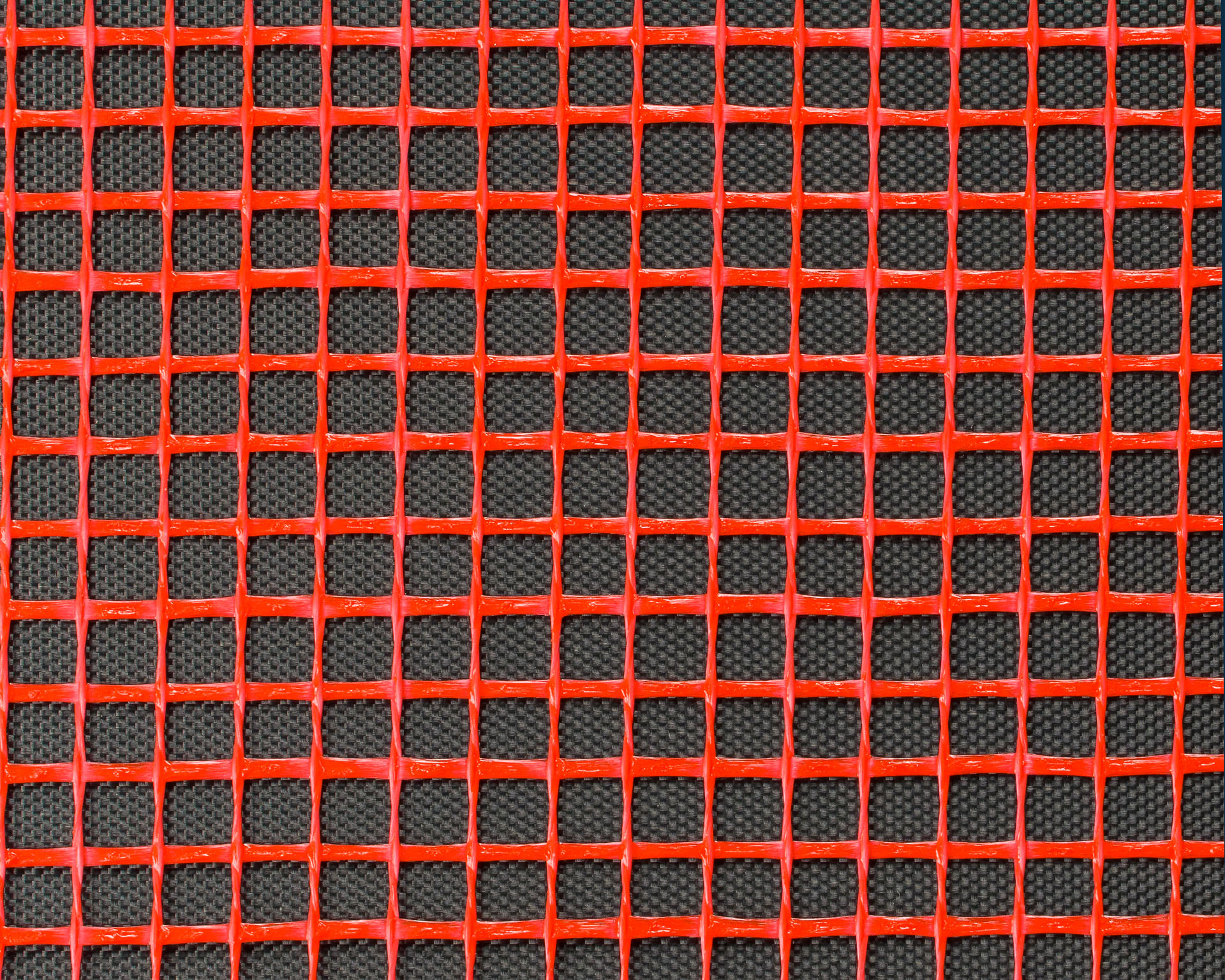

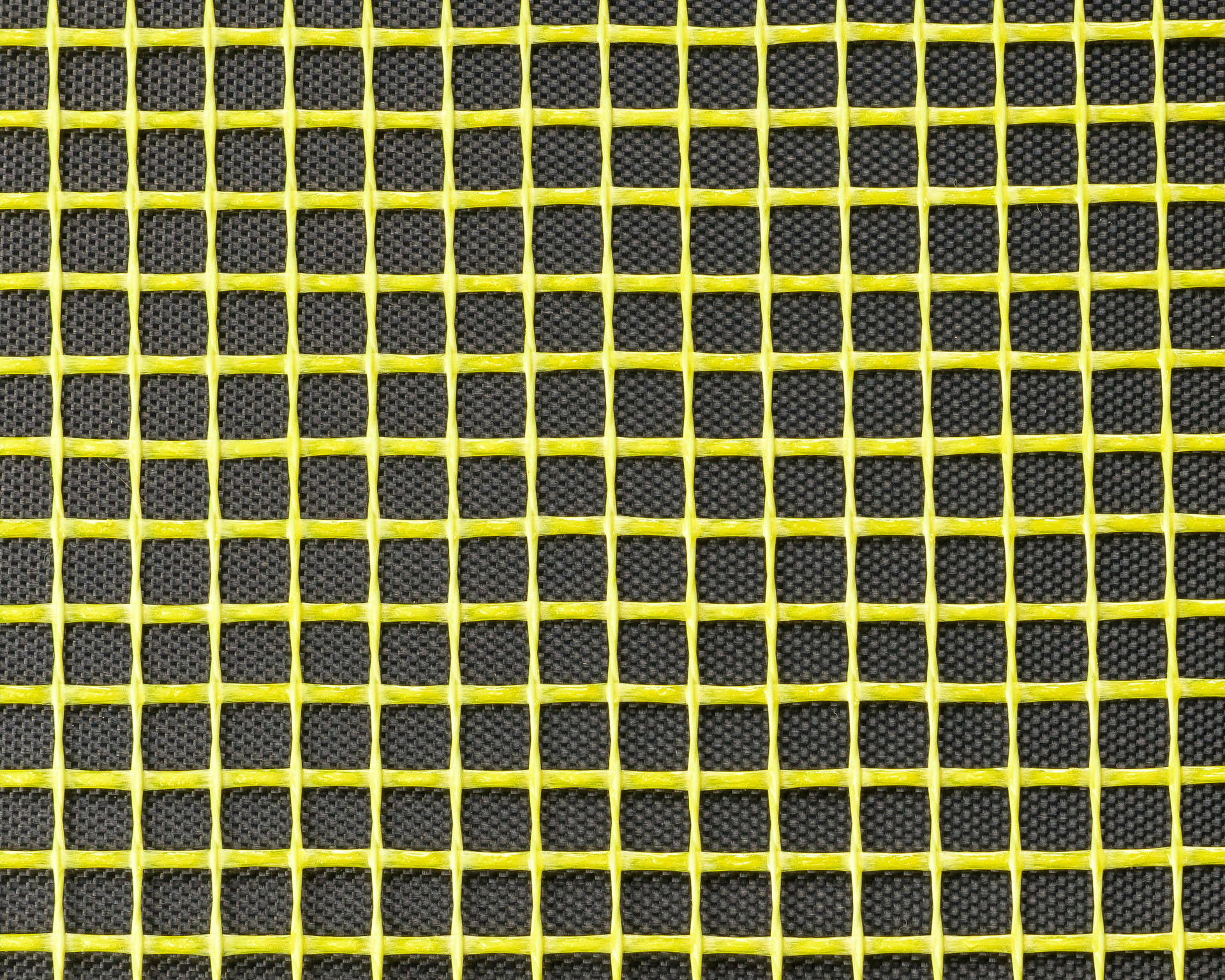

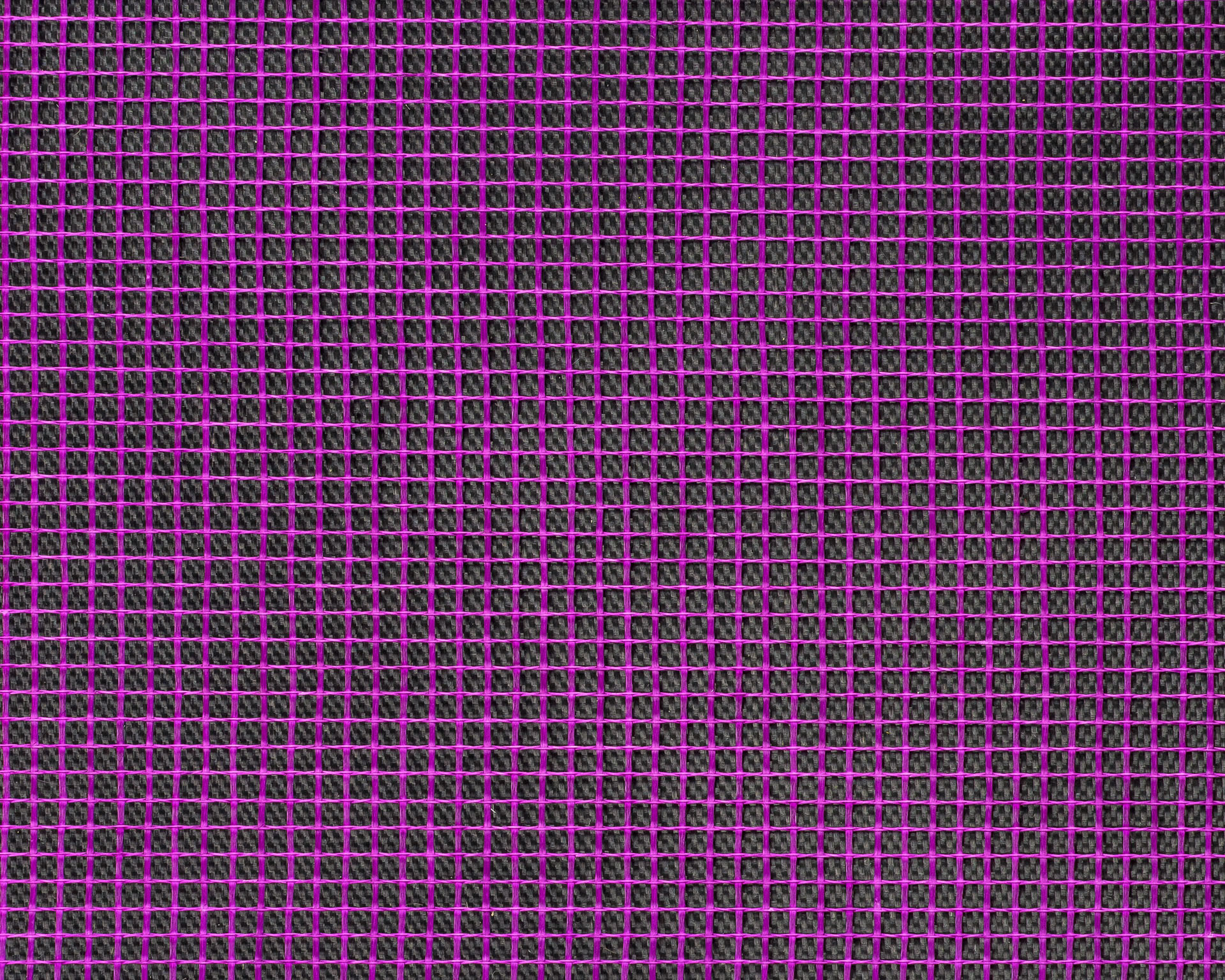

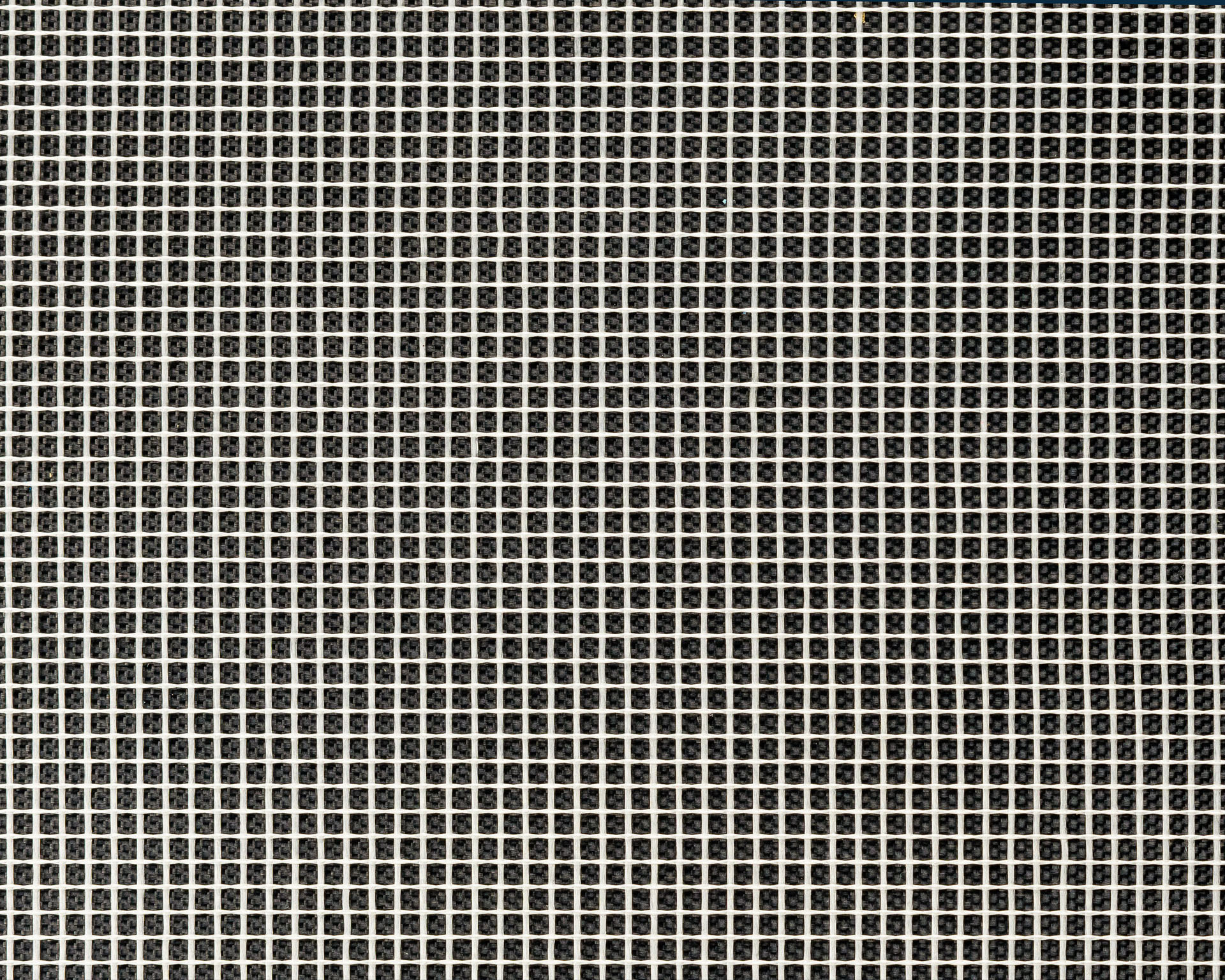

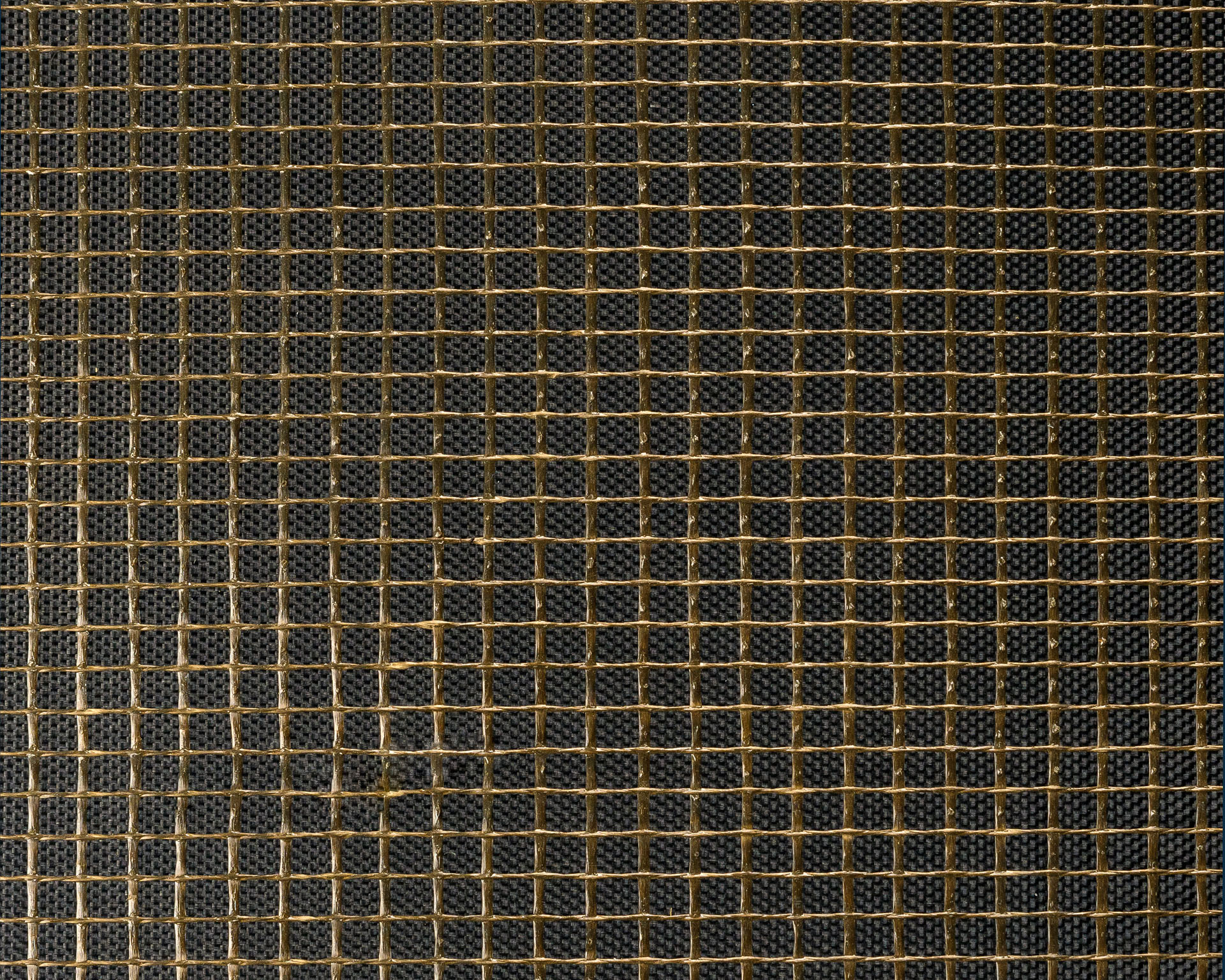

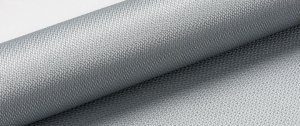

Glass grids

The glass grid is made from fiberglass.

- Alkali resistant

- High temperature resistant

- Possible colors

- Structural reinforcement

- Heat insulation

- Thermal insulation

| Reference | Composition | Weight (g / m²) | Width (mm) | Length (ml) | Number of warp threads | Number of weft threads |

| 970 | Fiberglass | 97 | 1000 | 100 | 10.1 / cm | 5.5 / cm |

| 780 | Fiberglass | 78 | 1000 | 100 | 12 / cm | 7.5 / cm |

| 710 | Fiberglass | 71 | 1000 | 100 | 4.88 / cm | 3.8 / cm |

| 659 | Fiberglass | 57 | 1000 | 25-1000 ml | 7.5 / cm | 3.75 / cm |

| 1450 | Fiberglass | 145 | 1000 | 100 | 1.4 / cm | 1.4 / cm |

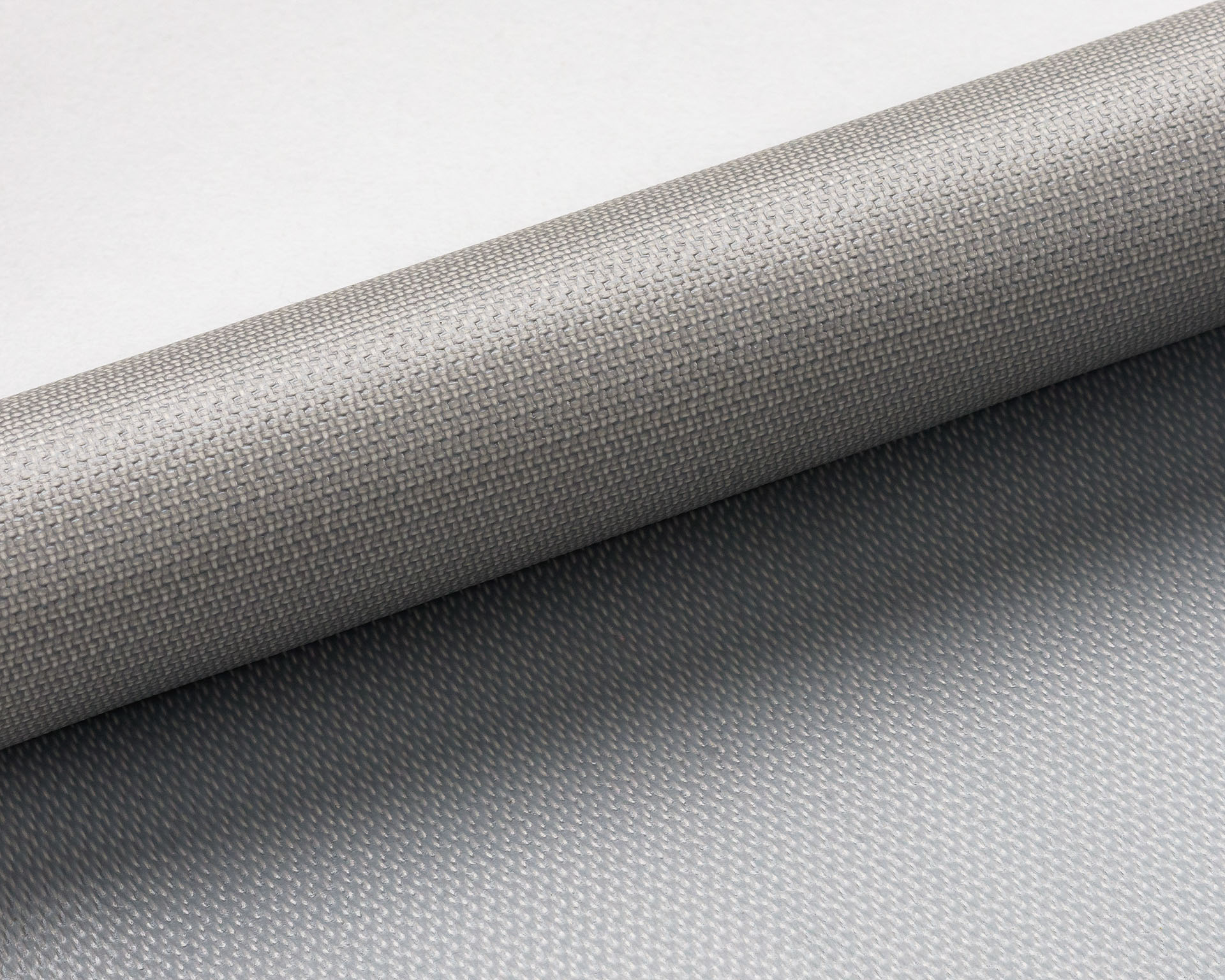

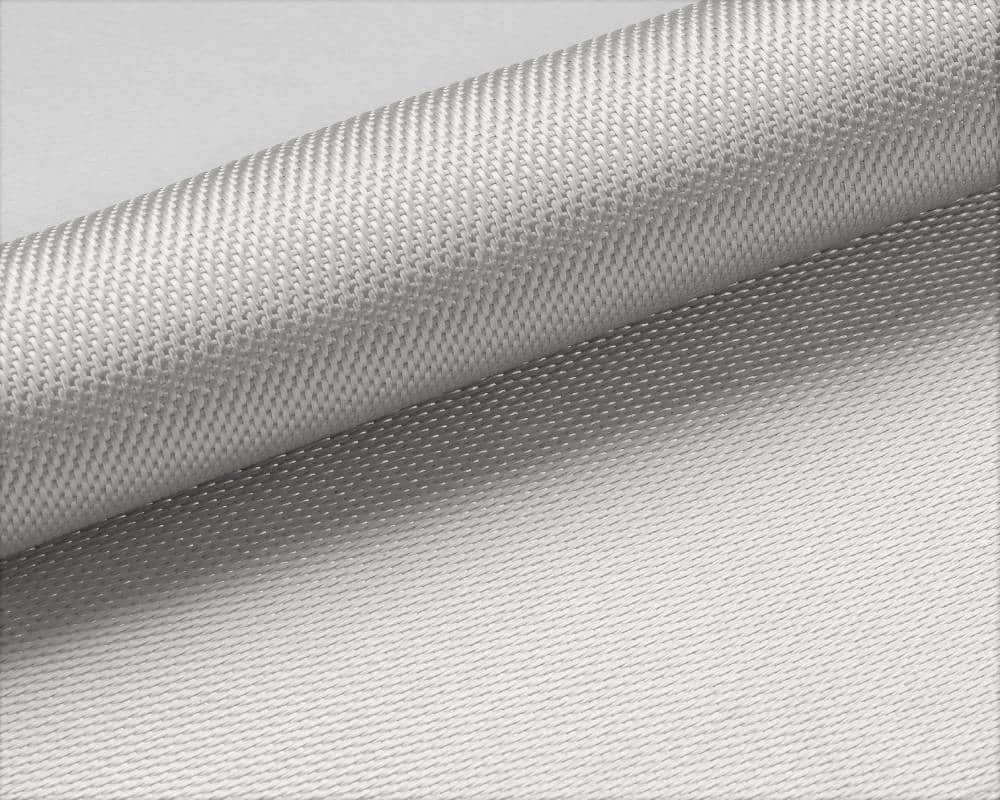

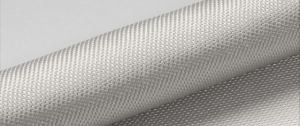

Glass fabrics

Glass fabrics are made from a fiberglass that withstands temperatures up to 800°C. Likewise, it is incombustible and thanks to its chemical resistance, it is ideal for specific industrial applications.

- Incombustible

- Temperature resistance

- Insulating

- Natural material

- Ecologically pure and harmless to human health

- Foundry

- Thermal insulation and heat insulation

- Steel industry

- Glass industry

- Heat protection

The caramelized glass fabric undergoes a desizing treatment which caramelizes the fiber. This treatment increases the temperature resistance performance and limits the release of smoke during the first temperature rise.

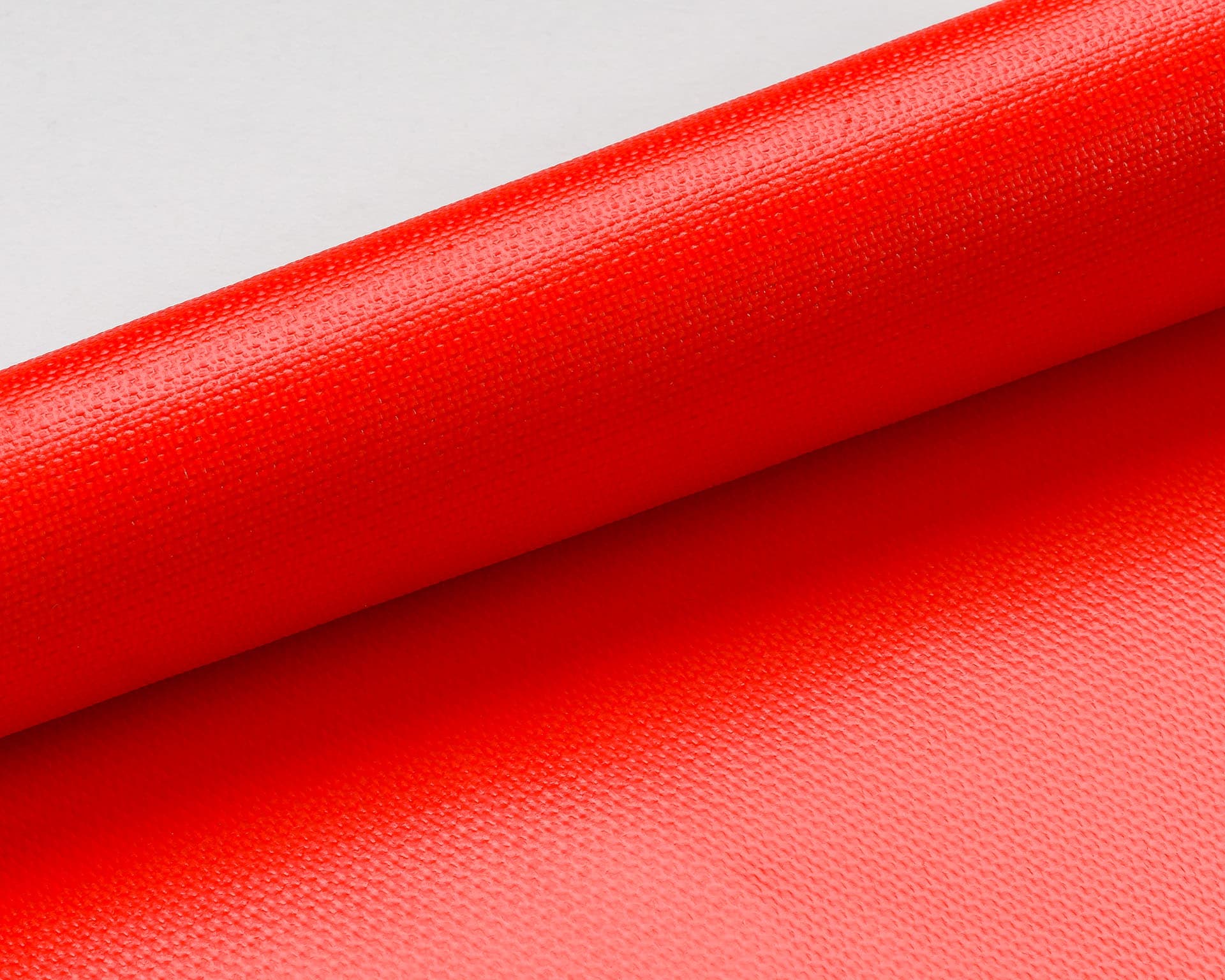

Polyurethane is an organic polymer used in textile coating processes. It provides airtightness and good resistance to fraying. The polyurethane can be dyed in the mass according to a standard or specific color. For grinding or welding protection applications, the polyurethane coating slows down the penetration of the textile by incandescent scrapes.

The anti-fraying treatment process involves impregnating the fiber with an acrylic-based formulation to fix it.

Polyvinyl chloride, commonly called PVC, is a fusible material used in particular in coating processes on textiles. This coating provides water and dust tightness. The PVC coated fabric can be assembled by welding, providing waterproofing and rapid assembly.

The unbleached glass fabric has not undergone any transformation or preparation.

Vermiculite is a natural mineral which has excellent insulation and fire resistance properties. The vermiculite coating provides resistance to high temperatures of up to 1000 ° C over a short period of time. Glass fabrics with a vermiculite coating are used in particular in the fields of welding protection or to protect incandescent projections (metallurgical industry, foundry, etc.)

Polytetrafluoroethylene (PTFE sign) – commonly called TEFLON® after the name of the trademark registered by the American company Dupont de Nemours – is a semi-crystalline, thermostable fluoropolymer (-200 ° C – + 260 ° C). The TEFLON® coating gives the textile a strong sliding power and improves resistance to chemical agents.

Polytetrafluoroethylene (PTFE sign) – commonly called TEFLON® after the name of the trademark registered by the American company Dupont de Nemours – is a semi-crystalline, thermostable fluoropolymer (-200 ° C – + 260 ° C). The TEFLON® coating gives the textile a strong sliding power and improves resistance to chemical agents.

Aluminum lamination increases the resistance properties of radiant heat.

The 800°C high temperature treatment is made from a silicate-based formulation, which gives the fabric excellent technical characteristics with very high temperature resistance up to 800°C.

Silica fabrics

These fabrics, composed of silica fibers, are materials resistant to high temperatures. They meet most industrial requirements in terms of temperature resistance, in many applications where temperature resistance greater than nearly 1000 ° C is required.

- High temperature resistance

- Good insulation capacity

- Strengthens thermal insulation/li>

- Insulation/Heat insulation

- Passive fire protection

- Heat shield / Anti-heat tarpaulin protection

- Oven curtains

Super high temperature fabric

The super high temperature fabric is designed to maintain strength and flexibility at high temperatures. This product is ideal for insulating or protecting tubing, pipes (or other structures that may be wrapped) in very high temperature applications.

- Permeable- lightweight- flexible and chemically inert

- Stabilizes edges due to weaving design

- Designed to maintain flexibility at extremely high temperatures

- Reinforcement in the insulation of blankets, cushions

- Wrap wires, and joints pipes

Very high temperature fabrics have excellent thermal characteristics which allow them to obtain resistance up to 1100 ° C and very good insulating properties.

Thanks to their excellent thermal characteristics, very high temperature fabrics can withstand up to 1350 ° C. They also have very good insulating properties.

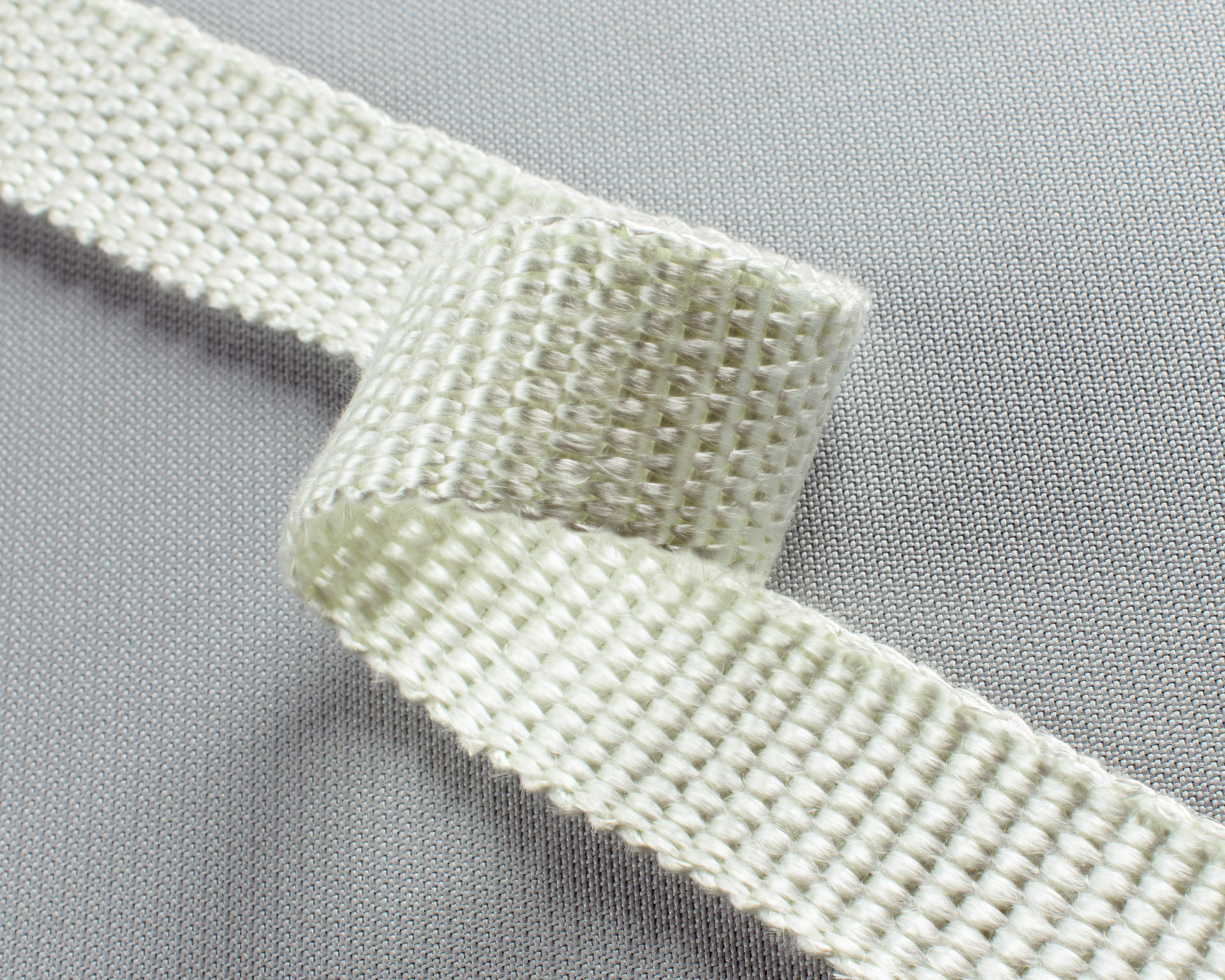

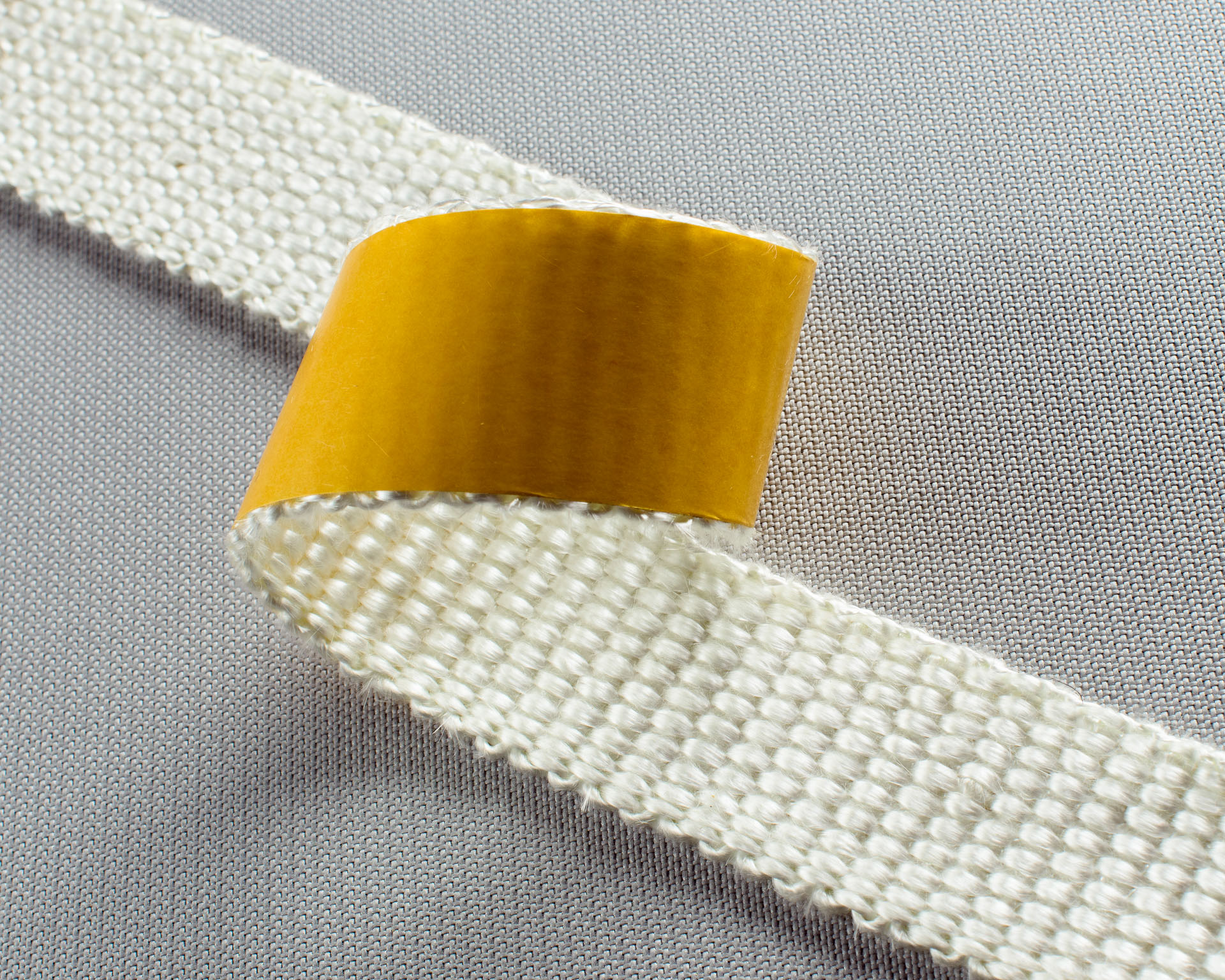

Technical tapes

Apronor technical tapes are manufactured to meet the needs of industry and construction professionals. Our company offers tapes designed for applications up to 1200°C. Our range consists of different models including ribbons of glass, adhesive glass, caramelized, silica, para-aramids, carbon… etc.

Glass ribbons

Apronor Glass Tapes are narrow width woven glass fabrics forming a tape for high temperature applications.

- Adaptability for all types of angles

- High temperature resistance

- Solidity

- Abrasion resistance

- Very good transparency

- Sandblasting

- Thermal insulation

- Seals

- Tissue fixation

Apronor Glass Tapes are narrow width woven glass fabrics forming a tape for high temperature applications.

| Reference | Composition | Weight (g / ml) | Width (mm) | Length (ml) | Unconstrained temperature | FLASH temperature | Thickness |

| RUBV 1168 50 | Fiberglass | 20 | 50 | 50 | 550 ° C | 600 ° C | 0.4 |

| RUBV 1168 100 | Fiberglass | 40 | 100 | 50 | 550 ° C | 600 ° C | 0.4 |

| RUBV25-1 | Fiberglass | 20 | 25 | 50 | 550 ° C | 600 ° C | 1 |

| RUBV20-2 | Fiberglass | 20 | 20 | 50 | 550 ° C | 600 ° C | 2 |

| RUBV30-2 | Fiberglass | 30 | 30 | 50 | 550 ° C | 600 ° C | 2 |

Apronor adhesive glass tapes consist of a glass fabric side and an adhesive side. Placed on a glass ribbon, the adhesive facilitates its positioning during installation.

| Reference | Composition | Weight (g / ml) | Width (mm) | Length (ml) | Unconstrained temperature | FLASH temperature | Thickness |

| 1168 ADV 100 ADV | Fiberglass + 1 adhesive side | 45 | 100 | 50 | 550 ° C | 600 ° C | 0.4 |

| RUBV40-3 ADV | Fiberglass + 1 adhesive side | 65 | 40 | 50 | 550 ° C | 600 ° C | 3 |

The caramelized glass ribbons undergo a desizing treatment which caramelizes the fiber. This treatment increases the temperature resistance performance and limits the release of smoke during the first temperature rise.

| Reference | Composition | Weight (g / ml) | Width (mm) | Length (ml) | Unconstrained temperature | FLASH temperature | Thickness |

| RUBVC 925/25 | Caramelized fiberglass | 15 | 25 | 50 | 550 ° C | 600 ° C | 0.7 |

| RUBVC 925/75 | Caramelized fiberglass | 45 | 75 | 50 | 550 ° C | 600 ° C | 0.7 |

Silica ribbons

Silica ribbons are made of silica fibers and can withstand temperatures up to 1100°C.

- Thermal resistance

- Good flexibility

- Low irritation

- Boiler

- Oven

- Heat insulation

- Cable protection

| Reference | Composition | Weight (g / ml) | Width (mm) | Length (ml) | Thickness |

| RUBS20-2 | Silica fiber | 20 | 20 | 50 | 2 |

| RUBS30-2 | Silica fiber | 33 | 30 | 50 | 2 |

| RUBS50-2 | Silica fiber | 54 | 50 | 50 | 2 |

| RUBS100-2 | Silica fiber | 98 | 100 | 50 | 2 |

| RUBS30-3 | Silica fiber | 45 | 30 | 50 | 3 |

| RUBS50-3 | Silica fiber | 68 | 50 | 50 | 3 |

| RUBS100-3 | Silica fiber | 136 | 100 | 50 | 3 |

| RUBS30-5 | Silica fiber | 54 | 30 | 50 | 5 |

| RUBS50-5 | Silica fiber | 85 | 50 | 50 | 5 |

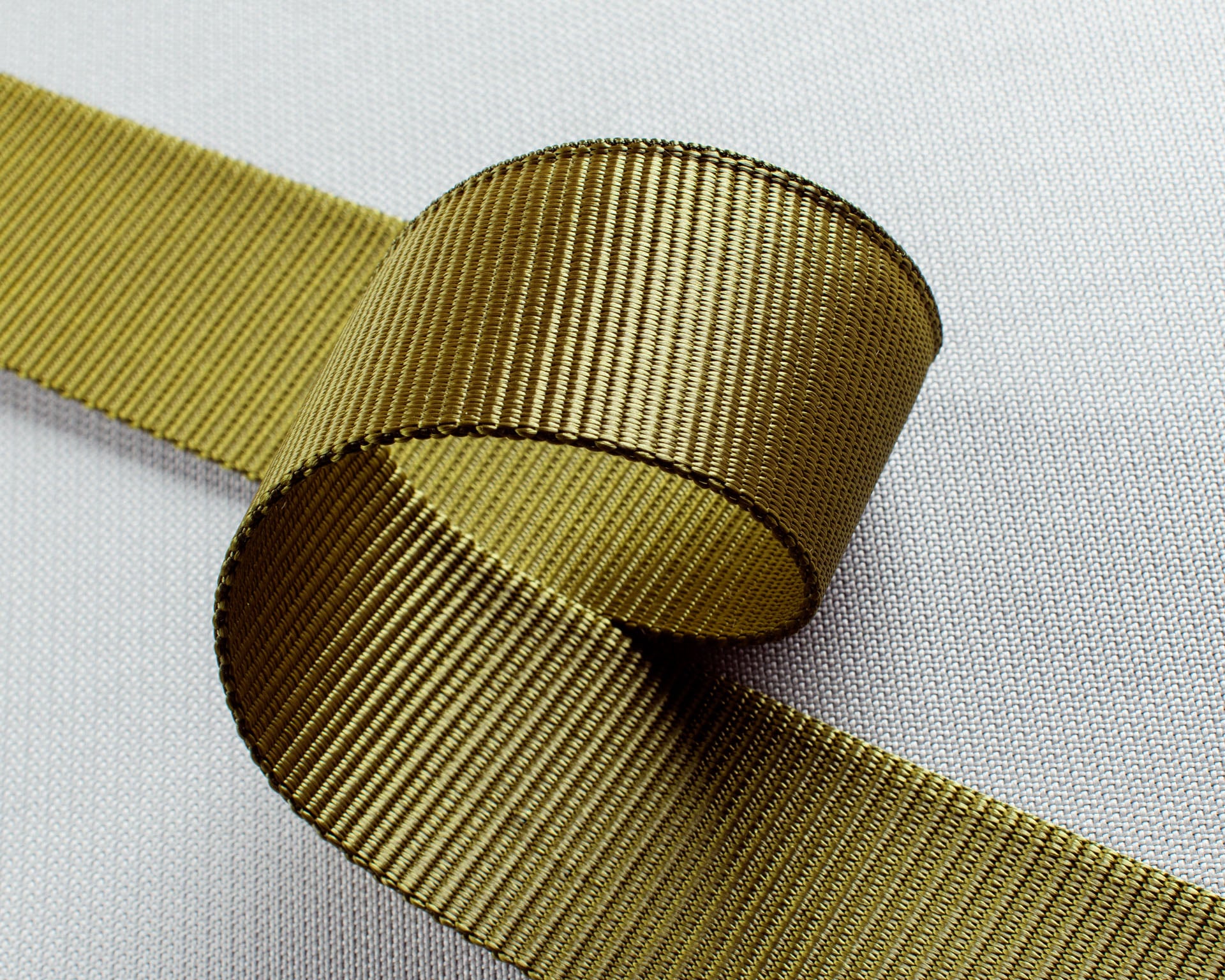

Kevlar® para-aramid tapes

Kevlar® is a registered trademark of aramid fiber produced by the firm Dupont de Nemours. Also called poly-para-phenylene-terephthalamide (PPD-T), it was discovered by two company researchers, Stéphanie Kowlek and Herbert Blades, already at the origin of Nomex® which is heat resistant. There are several types of Kevlar depending on the intended use, the most common being Kevlar 49.

- Tenacity: 16,5 to 20,6 cN/dtex

- Elongation: 3,0 to 4,0%

- Modulus: 60 to 80 GPa

- Degradation temperature: 482°C

- Max continuous use temperature: 240°C

- Flame Spread: no

- Density: 1,44g/cm3

- Colors: yellow

- Excellent abrasion resistance

- Mechanical resistance

- Heat protection

- Cable protection

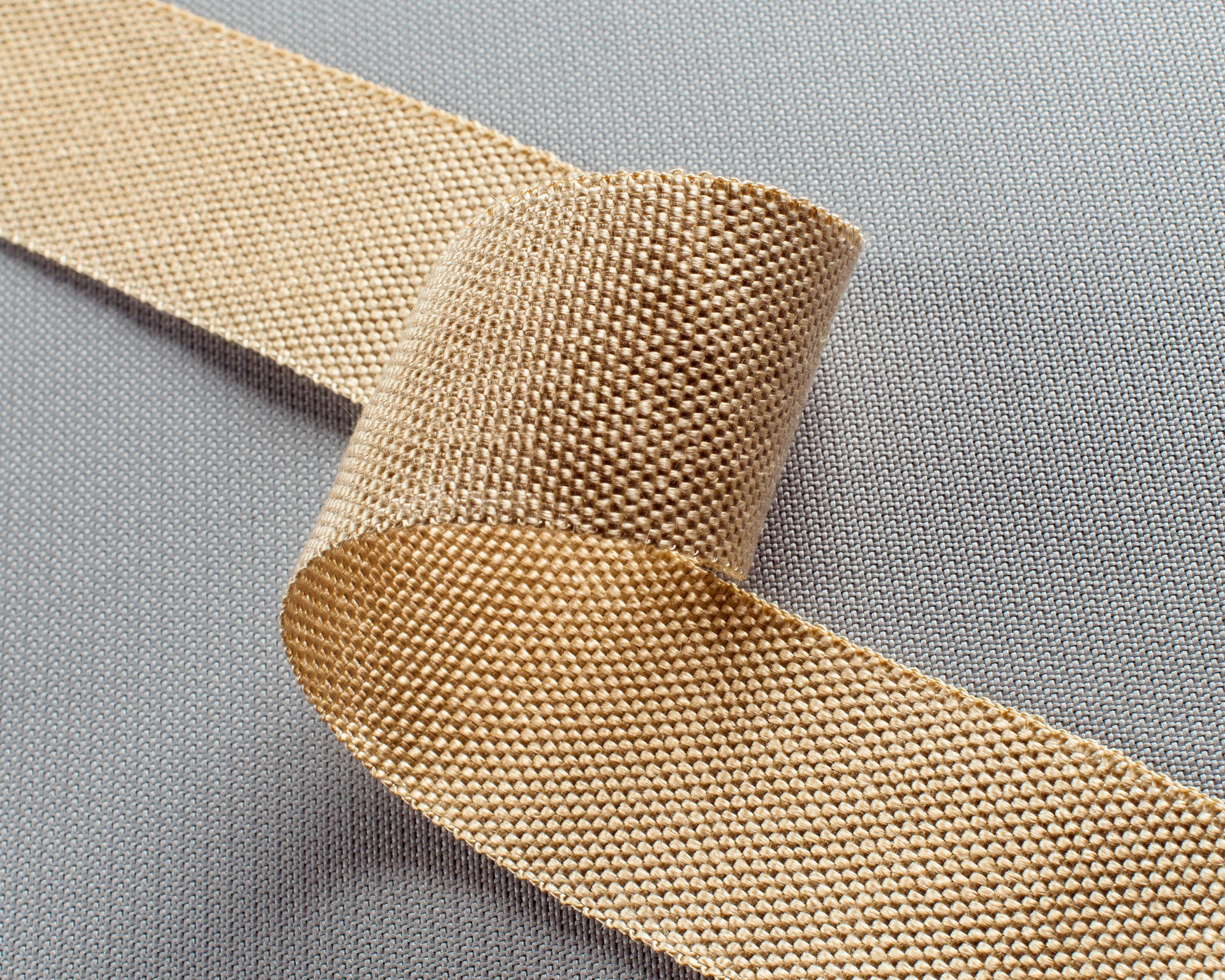

Nomex® Meta-Aramid Tape

Nomex Meta-Aramid Tape is a heat and flame resistant product for use in protective clothing). It has excellent chemical and thermal stability.

- Width (mm): from 5 to 550

- Weight (g/m2): varying from 65 to 3000

- Weave: Taffeta, Twill, Satin, One-way, UD Weft

Aramid Stainless steel/aramid metal tapes

Made with our stainless steel – aramid spun threads, our woven bands are produced by multi-layer weaving.

- Excellent wear resistance

- High temperature resistance

- Glassware

| Product reference | Linear mass (g / m) | Width (mm) | Thickness (mm) |

| STB 12-45 / 40A | 45 | 12 | 3.5 |

| STB 16-50 / 40A | 50 | 16 | 4 |

| STB 25-60 / 40A | 60 | 25 | 2.4 |

| STB 25-120 / 40A | 120 | 25 | 4.8 |

| STB 50-110 / 40A | 110 | 50 | 2.4 |

| STB 50-220 / 40A | 220 | 50 | 4.8 |

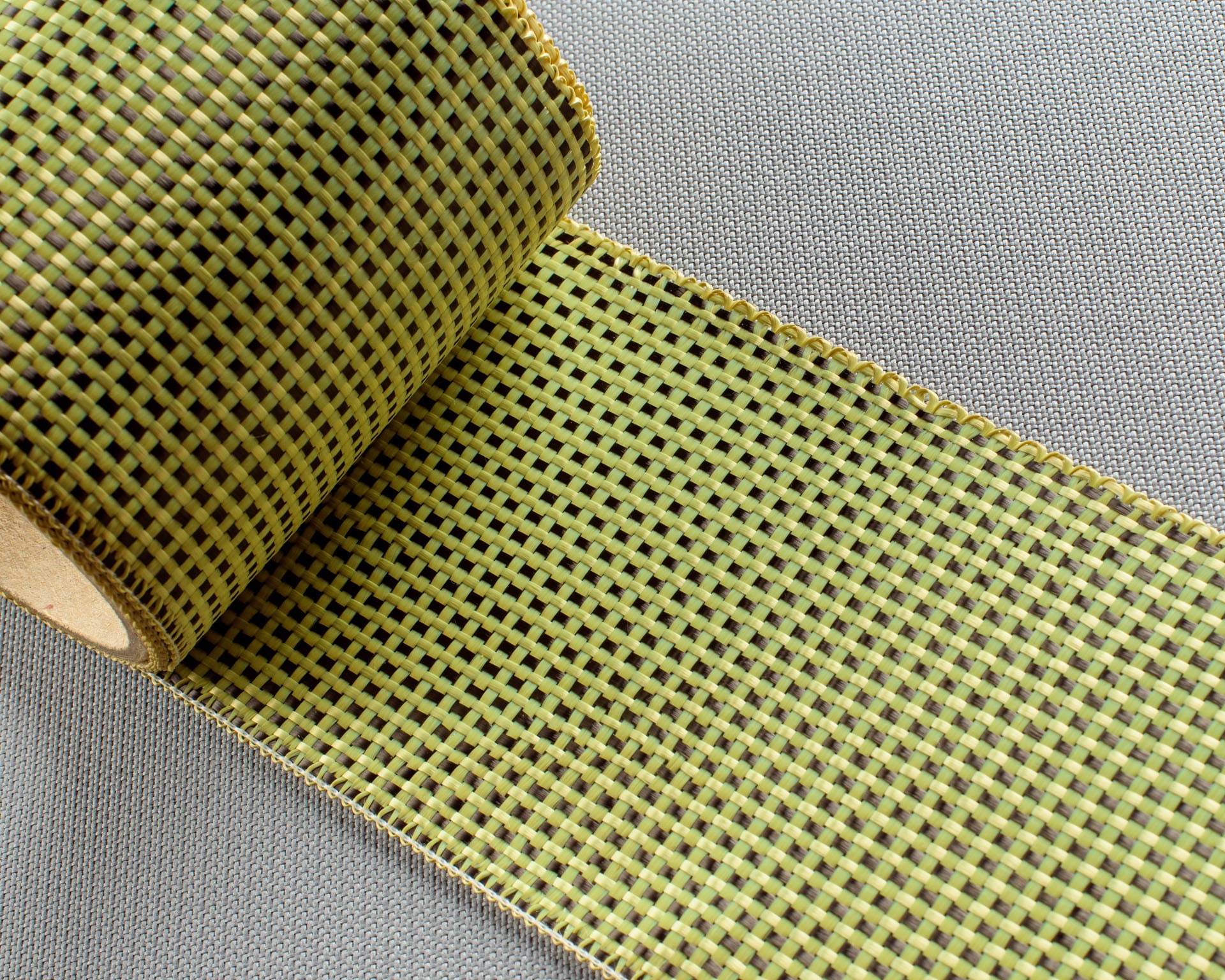

Carbon ribbons

This tape is made from carbon fibers.

- Ribbons woven from 1k, 3k, 6k, 12k carbon threads

- Width (mm) : from 5 to 550

- Weight (g/m2) : varying from 90 to 3000

- Features: Taffeta, Twill, Satin, Unidirectional, UD Weft.

- Corrosion insensitive

- Resistance to alkalis, acids and organic solvents

- Vibration absorption

- Electrical conductivity

- Electromagnetic protection

- Solidity

- Construction

- Surf boards

| Reference | Composition | Weight (g / m²) |

| RUBC200 | Taffeta | 200 |

| RUBC400 | Taffeta | 400 |

| RUBC600 | Taffeta | 600 |

Other technical tapes

- Hybrid carbon/aramid tape

- Double-sided carbon/glass tape

- Carbon tape with central unidirectional reinforcement

- Undetectable ribbon, etc.

Braids, beads and technical sleeves

Apronor manufactures braids, beads and technical sleeves for specific applications in high temperature conditions.

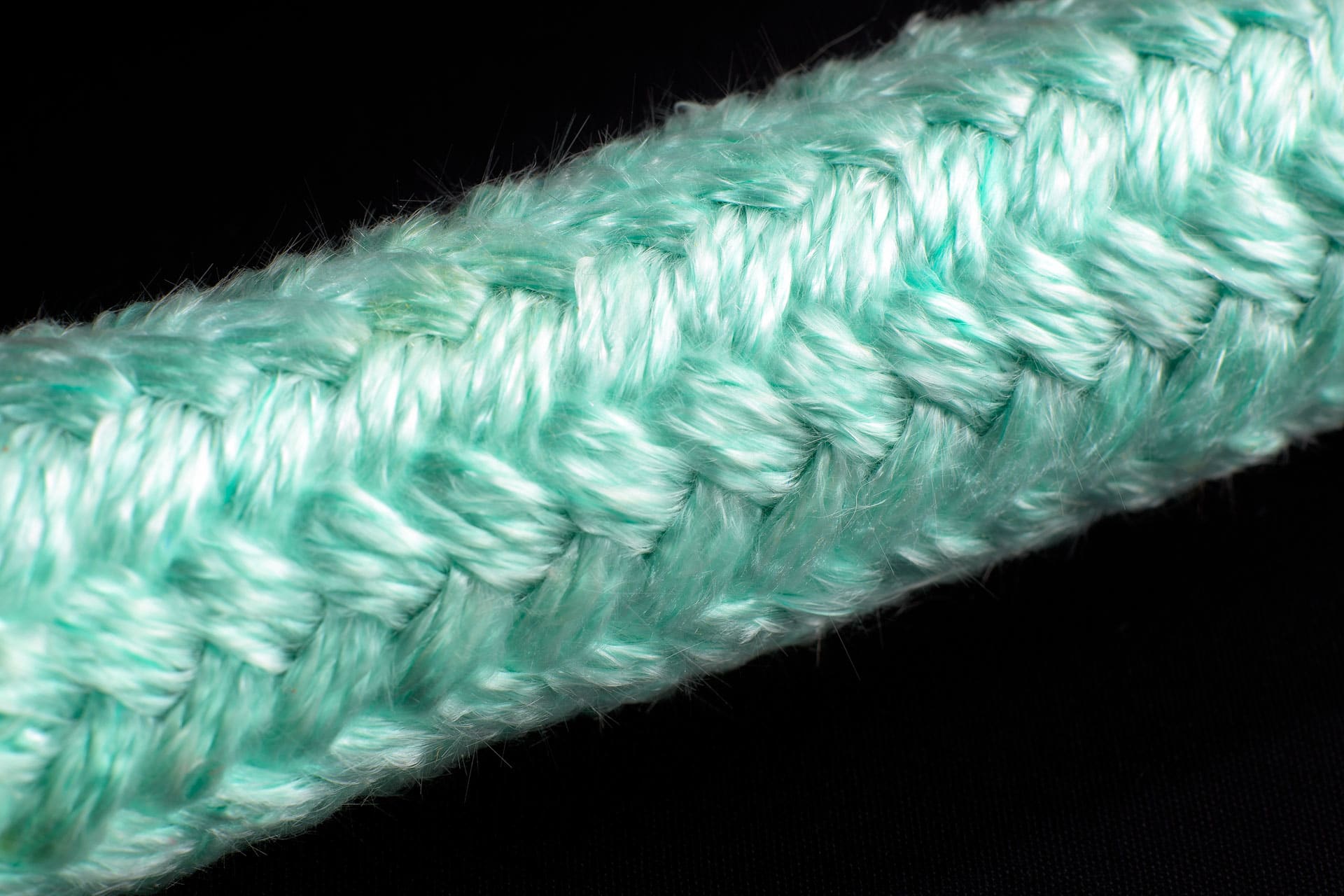

Technical braids

Apronor manufactures three main categories of technical braids: glass, 800 ° C glass and silica. They are generally used as insulation joints for well-defined applications such as thermal protection and insulation.

- High temperature resistance

- Excellent flexibility

- Excellent mechanical resistance

- Insulation Joints

- Seals

- Ovens and exhaust pipes

Made from non-alkaline E-glass, the texture ensures high build-up volume and therefore good insulation values.

- Filament diameter 6–11 μm

- Non-flammable (according to DIN 4102)

- Loss on ignition <1.5%

| Reference | Armor | Weight GR / ML | Diameter (mm) | Temperature |

| TREV / 600/6 | Knitting / Braiding | 31 | 6 | 550 ° C |

| TREV / 600/8 | Knitting / Braiding | 41 | 8 | 550 ° C |

| TREV / 600/10 | Knitting / Braiding | 63 | 10 | 550 ° C |

| TREV / 600/12 | Knitting / Braiding | 100 | 12 | 550 ° C |

| TREV / 600/15 | Knitting / Braiding | 156 | 15 | 550 ° C |

| TREV / 600/20 | Knitting / Braiding | 280 | 20 | 550 ° C |

Made with non-alkaline E-glass, the texture has a high build-up volume and offers good insulation values.

- Filament diameter 6–14 μm

- Non-flammable (according to DIN 4102)

- Loss on ignition <3%

| Reference | Armor | Weight (g / ml) | Diameter (mm) |

| TREV / 800/6 | Knitting / Braiding | 35 | 6 |

| TREV / 800/8 | Knitting / Braiding | 48 | 8 |

This product is made from special high thermal resistance SiO2 glass fibers. It is characterized by a low thermal conductivity value and does not irritate the skin.

- Filament diameter 6–9 μm

- Non-flammable (according to DIN 4102)

- Loss on ignition <3%

| Reference | Armor | Weight (g / ml) | Diameter (mm) |

| TRES / 1100/6 | Knitting / Braiding | 32 | 6 |

| TRES / 1100/8 | Knitting / Braiding | 65 | 8 |

| TRES / 1100/10 | Knitting / Braiding | 80 | 10 |

| TRES / 1100/12 | Knitting / Braiding | 120 | 12 |

| TRES / 1100/15 | Knitting / Braiding | 170 | 15 |

| TRES / 1100/20 | Knitting / Braiding | 275 | 20 |

Made with our stainless steel – aramid yarns, these braids combine flexibility and good mechanical and thermal resistance. They are packaged in 25 m rolls.

| Product reference | Linear mass (g / m) | Inner diameter (mm) | Composition |

| TRIA / BTRB 16- 48 / 40A | 48 | 16 | stainless steel - aramid |

Musical note seals

The musical note-shaped gasket is a textile tube which consists of a lining and a lip to secure it. It is the lined tube which performs the sealing or insulation function. It is used to make the wedging between two walls for the protection between the supports in the industrial fields.

The assembled joints / bands are made by assembling a base material layer by layer until the required dimensions are obtained. It is possible to provide this type of seal with a core made of a different material.

- Flexibility

- Mechanical resistance

- Excellent thermal resistance

- Seals

- Appliances

- Fire protection

- Industrial furnaces

Technical ducts

Technical sheath is commonly used as a thermal protective sheath to insulate and protect cables, pipes, and wires exposed to high temperatures.

- Resistance to humidity, ozone and UV

- Good resistance to usual chemical atmospheres

- Compatibility with most impregnation varnishes

- Internal wiring of class H and C rotating machines (motors, alternators, generators, transformers, chokes, etc.)

- Insulation up to 250 ° C

- Electrical and electronic constructions

- Heating devices

- Lighting, automotive, measurement, regulation …

OTHER POSSIBLE FEATURES

- Diameter (mm):from 1 to 250

- Armor: Unidirectional, Bi-axial (45 °), Tr i-axial (45 ° + UD)

| Reference | Weight (g / ml) | Diameter (mm) | Temperatures |

| GAIV / 600/10 | 14 | 10 | 550 |

| GAIV / 600/20 | 37 | 20 | 550 |

| GAIV / 600/30 | 46 | 30 | 550 |

| GAIV / 600/40 | 74 | 40 | 550 |

| GAIV / 600/50 | 101 | 50 | 550 |

| GAIV / 600/80 | 148 | 80 | 550 |

| GAIV / 600/120 | 221 | 120 | 550 |

| GAIV / 600/150 | 258 | 150 | 550 |

| GAIV / 600/200 | 367 | 200 | 550 |

- Continuous operating temperature: -60 ° C to + 250 ° C class H

- Self-extinguishing – satisfies VW1 test according to UL 1441

- Very high flexibility

- Electric halogen free

- Dry dielectric strength: > 3 Kv

| Reference | Inner Diameter - Nominal Value (mm) | Diameter tolerance (mm) | Minimum wall thickness (mm) | Linear mass (kg / km) |

| GAIVSIR / 1 | 1 | ± 0.15 | 0.2 | 4.4 |

| GAIVSIR / 2 | 2 | ± 0.2 | 0.2 | 6.7 |

| GAIVSIR / 4 | 4 | ± 0.25 | 0.3 | 12.1 |

| GAIVSIR / 6 | 6 | ± 0.25 | 0.3 | 18.6 |

| GAIVSIR / 8 | 8 | ± 0.25 | 0.3 | 26.2 |

| GAIVSIR / 10 | 10 | ± 0.5 | 0.4 | 35 |

| GAIVSIR / 12 | 12 | ± 0.5 | 0.4 | 57.5 |

| GAIVSIR / 14 | 14 | ± 1 | 0.4 | 78.1 |

| GAIVSIR / 20 | 20 | ± 1 | 0.4 | 147.2 |

| GAIVSIR / 25 | 25 | ± 1 | 0.4 | 206.1 |

| GAIVSIR / 30 | 30 | ± 2 | 0.4 | 266.2 |

| GAIVSIR / 35 | 35 | ± 2 | 0.4 | 327.5 |

- Diameter: from 1 to 250 mm

- Armor: Unidirectional, Bi-axial (45 °), Tr i-axial (45 ° + UD)

| Reference | Weight (g / ml) | Diameter (mm) |

| GAIC10 | 9 | 10 |

| GAIC20 | 27 | 20 |

| GAIC30 | 41 | 30 |

| GAIC50 | 54 | 50 |

| GAIC80 | 108 | 60 |

| GAIC90 | 136 | 80 |

| GAIC100 | 217 | 100 |

| GAIC140 | 217 | 140 |

- Diameter: from 1 to 250 mm

- Armor: Unidirectional, Bi-axial (45 °), Tri-axial (45 ° + UD)

| Reference | Weight (g / ml) | Diameter (mm) |

| GAIA10 | 11 | 10 |

| GAIA20 | 23 | 20 |

| GAIA30 | 34 | 30 |

| GAIA50 | 68 | 50 |

- Diameter: from 1 to 250 mm

- Armor: Unidirectional, Bi-axial (45 °), Tri-axial (45 ° + UD)

- Preform braiding

- Composition: aramid/glass

50% CARBON COATINGS 50% ARAMID

| Reference | Weight (g / ml) | Diameter (mm) |

| GAICA20 | 26 | 20 |

| GAICA30 | 50 | 30 |

50% CARBON COATINGS 50% ARAMID

| Reference | Weight (g / ml) | Diameter (mm) |

| GAICA20 | 26 | 20 |

| GAICA30 | 50 | 30 |

Need high temperature insulating textiles?

Glass fabric

Glass fabric Glass fiber mesh

Glass fiber mesh PTFE coated glass fabrics

PTFE coated glass fabrics Caramelised glass fabrics

Caramelised glass fabrics Polyurethane-coated glass fabrics

Polyurethane-coated glass fabrics High temperature glass textiles

High temperature glass textiles Glass fabrics + aluminium lamination

Glass fabrics + aluminium lamination PVC coated glass fabrics

PVC coated glass fabrics Ecru silica Fabrics

Ecru silica Fabrics Vermiculite silica Fabrics

Vermiculite silica Fabrics Steel reinforcement (V4A) silica Fabrics

Steel reinforcement (V4A) silica Fabrics Glass needle felts

Glass needle felts Panox Welding Black® needle felts

Panox Welding Black® needle felts Glass needle felts + aluminium lamination

Glass needle felts + aluminium lamination Technical fabrics

Technical fabrics Technical nets & films

Technical nets & films Protective fabrics

Protective fabrics High temperature insulating felts

High temperature insulating felts technical sewing threads, ribbons

technical sewing threads, ribbons Adhesives and technical glues

Adhesives and technical glues Passive fire protection

Passive fire protection